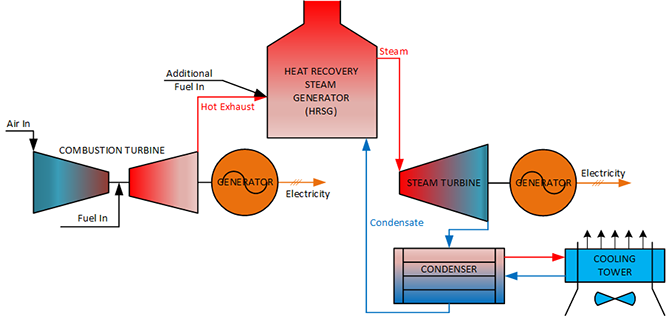

“Combined cycle” is a term used in the electric generating industry to describe a generating plant that has a sequential topping-bottoming cycle configuration. Fuel is used in the topping cycle (typically a combustion turbine generator) to generate electricity, and then high temperature waste heat from the topping cycle equipment is used to generate additional power in a bottoming cycle (typically a steam turbine generator). Unlike a combined heat and power (CHP) or cogeneration plant, which can have either a topping or bottoming cycle configuration and where waste heat is used for a useful non-generating purpose, in a combined cycle plant the waste heat is used for additional power generation only.

Welcome to Bridgestone Associates

Combined Cycle Power: History, Description & Uses

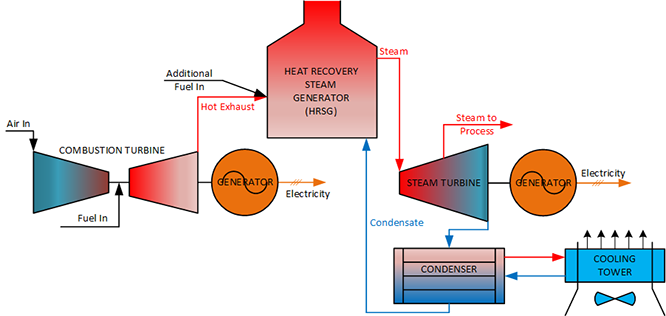

It is possible however to have a combined cycle plant that is also a cogeneration plant. These may be found at facilities such as oil refineries, paper mills, chemical plants, and steel mills where there is a large thermal and electric load (example: 42 MW Graphic Packaging CHP Plant & US Steel Coke Oven Gas Fired CHP Plant). In a combined cycle CHP plant, some of the waste heat, either directly from the topping cycle or more commonly from the bottoming cycle, is used for a useful non-generating purpose (e.g. process use). If taken from the bottoming cycle, it may be taken from the exhaust of the steam turbine if a back-pressure, non-condensing steam turbine is used, from an extraction point on the steam turbine, or from both. The diagram below shows an example of this where steam for process is taken from an extraction point on the steam turbine.

The use of a combined cycle configuration is not new. The first recognized combined cycle plant was installed by an Austrian utility NEWAG at their Korneuburg A plant in Austria in 1961. The plant had two 25-MW BBC Type 12 combustion turbines, a 25-MW steam turbine, and a HRSG with supplementary firing. It had an overall efficiency of about 32.5%. Today, large combined cycle plants have efficiencies of over 60% which may be compared to a typical large coal fired plant with an efficiency of around 32 – 37% and a large simple cycle natural gas fired combustion turbine with an efficiency of 35 – 40%. This high efficiency is why combined cycle plants have become the configuration of choice for new grid-connected natural gas fired generating plants.

A good example of a highly efficient combined cycle plant is the planned 560 MW Gloucester City Combined Cycle Power Plant. Bridgestone Associates recently completed a comprehensive feasibility study for the developer of this natural gas fired combined cycle plant, to be built adjacent to the Delaware River in New Jersey, USA. The plant has an estimated net equipment heat rate of 62.7% (energy in to energy out efficiency) and an overall plant efficiency of 61.6% under ISO conditions (59 oF, 60% Relative Humidity, sea level). This means the plant’s overall heat rate is 5,542 Btu/kWh LHV (Lower Heating Value) while generating 555 MW. The planned plant will use a GE 7HA-02 natural gas fired combustion turbine in a single shaft configuration with a General Electric reheat steam turbine and a single GE generator. In this configuration the combustion and steam turbines will drive a single hydrogen cooled generator. The study completed by Bridgestone included detailed analysis of plant performance using Thermoflow’s GT-PROTM and GT-MASTERTM analysis software, analysis of local power market pricing, preparation of a detailed capital cost estimate, and development of comprehensive financial analysis model. [Note: since the original study was completed, GE uprated the plant capacity to 600 MW].

Why a combined cycle power plant?

The simple reason – efficiency. When compared to a traditional coal or gas fired plant (boiler or simple cycle combustion turbine), a combined cycle plant’s overall efficiency can be 20 – 30% greater. This means that fuel use is 20 – 30% less and the fuel cost per megawatthour is 20 – 30% lower. In a competitive wholesale electric grid market, this is highly important.

Because of the high efficiency of a combined cycle configuration, overall emissions per megawatthour are significantly lower than other fossil fueled generation sources. With the move to minimize and eliminate carbon dioxide (CO2) emissions from power generation, combined cycle plants help with this objective.

Because part of a combined cycle plant includes the steam cycle and it is necessary to allow time for the HRSG and steam turbine components to heat soak and come up to temperature thoroughly before full load operation, a combined cycle plant cannot reach full load from a cold start as quickly as a simple cycle combustion turbine. Therefore it is not ideal as a peaking plant. However, once at temperature, output levels can be changed quickly and, with the addition of a duct burner in the inlet to the HRSG, steam output can be varied up and down, providing the ability to also quickly increase or decrease steam turbine output. With its low heat rate (i.e. high efficiency), it is ideal as a baseload and intermediate load generating plant.

For more information on how combined cycle plants work, on their feasibility and costs, and on modeling their performance using GT-PRO and GT-MASTER, please contact us.

Get in Touch

Contact us and speak with a power generation expert about your next project.

Call

(610) 388-3600

solutions@brdgstn.com

Post A Comment