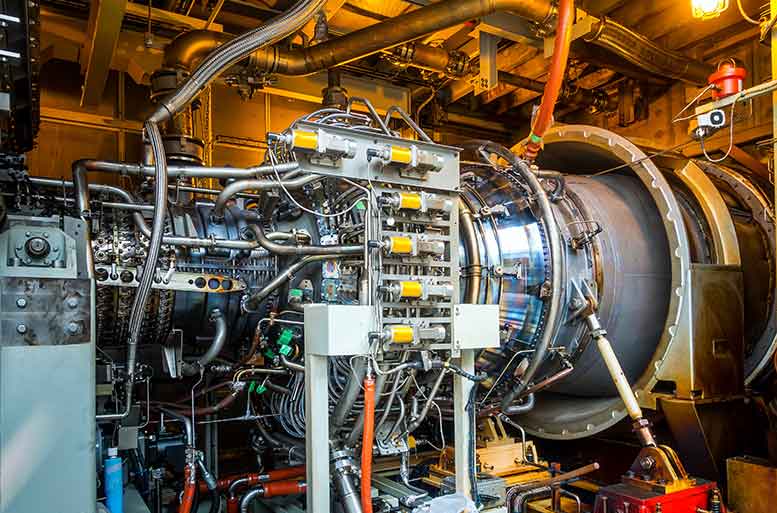

The choice between a turbine (steam or combustion) and reciprocating engine generator for a combined heat and power (CHP) or combined cooling, heat and power (CCHP) depends on a number of factors including the specific application, the balance between thermal and electrical, the type and quality of thermal required, the size, short-term or seasonal fluctuations in loads, fuel availability, etc. In general, combustion turbines are good for CHP and CCHP applications where there is a lot of high grade thermal (e.g. high pressure steam, chilled water, etc.) required. This is because the vast majority of the by-product waste energy is in the form of hot (900 – 1,050 oF) exhaust gas with little waste heat going elsewhere (e.g. radiated heat loss, lube oil coolers, water coolers, etc.). The waste heat from a reciprocating engine includes exhaust gas, jacket coolant, turbo intercooler, lube oil cooler, and radiated losses. The exhaust gas is typically 700 – 900 oF but there is relatively little volume when compared to a combustion turbine exhaust, so the ability to produce a lot of high grade thermal is limited. The engine jacket coolant, where the largest amount of waste heat can be recovered, is only 200 – 230 oF, so is useful for producing hot water but not steam.

Welcome to Bridgestone Associates

Turbines vs. Reciprocating Engine Generators

In general, a combustion turbine, either in simple or combined cycle, is the equipment of choice if you have a need for high pressure steam (e.g. over 100 psig) and in large quantity, where a reciprocating engine may be more appropriate for a CHP application where you need a lot of hot water (e.g. for sanitation, process, etc.).

Reciprocating engines in general are better for load following if you have an electrical load that varies as their efficiency does not vary significantly as you reduce their load unlike combustion turbines which become far more inefficient at lower loads.

Plant size does matter. There are few combustion turbines below about 3,000 kW and they are pretty inefficient. That doesn’t matter so much if you are capturing the waste heat but it does if you aren’t. Combustion turbines would be the choice for larger (typically 7,000 – 10,000 kW and above) plants and either reciprocating engines or combustion turbines in the 3,000 – 7,000 kW range, again though depending on the thermal requirements and balance between thermal and electrical.

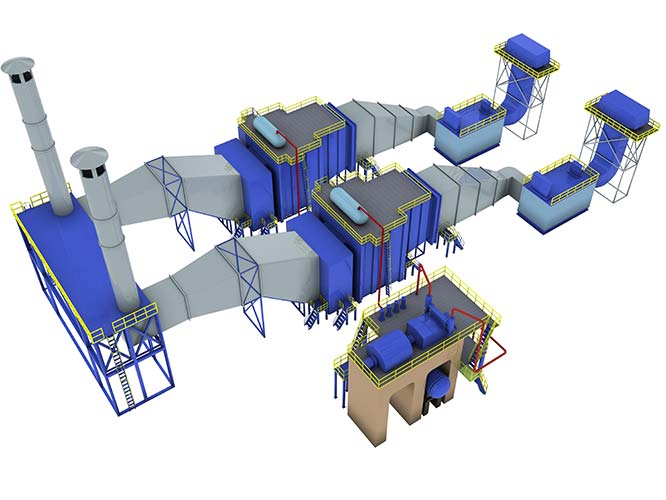

In a CCHP application, as a general rule of thumb, a 5,000 kW combustion turbine can produce about 2,600 – 2,800 RT (refrigeration tons) of chilled water using an absorption chiller. An equivalently sized reciprocating engine plant would be able to produce about 900 – 1,000 RT.

From a capital cost perspective, a natural gas fired reciprocating engine CHP plant is likely to be less expensive than a combustion turbine based plant. However its operating costs will typically be higher on a per kilowatt-hour basis as engines require more routine maintenance, lube oil changes, etc.

When we model projects for clients, we review all alternatives (turbines (simple and combined cycle) and engines, and combinations thereof) and their different configurations in order to develop the most cost effective approach that meets the client’s requirements. This allows us to provide a comparison between alternatives, how they meet the thermal and electrical requirements and any variations in those requirements, and their capital and O&M costs. We base our analyses on new equipment so we can compare total capital costs with data available in the industry, and then we look at ways to reduce those costs using secondary market (new surplus and refurbished used) equipment if appropriate, providing recommendations to our clients on the different alternatives and their respective values.

Get in Touch

Contact us and speak with a power generation expert about your next project.

Call

(610) 388-3600

solutions@brdgstn.com

Post A Comment