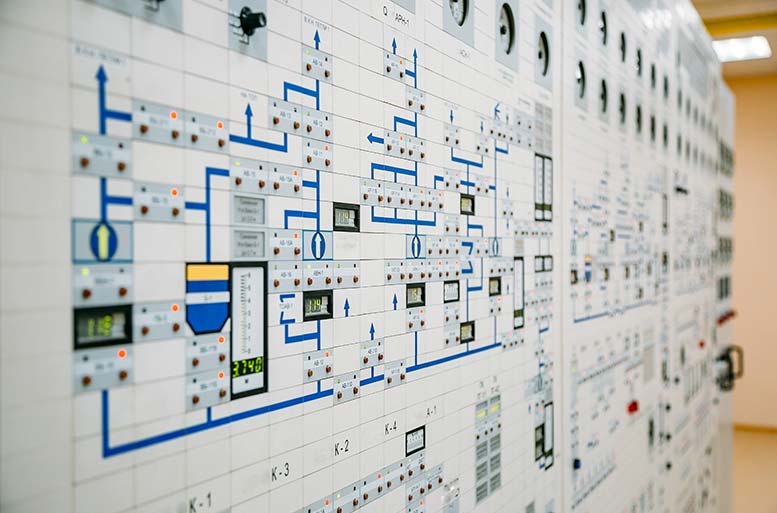

While these three levels help define the depth to which an energy audit is conducted and act as a good starting point for industrial and commercial facility energy efficiency scope discussions, they don’t necessarily cover all aspects of energy efficiency and process optimization that in total may provide considerable additional benefit to the facility owner. As the example above illustrates, understanding systems and processes can result in more than just energy efficiency improvements. In that case a simple energy audit might highlight the existing efficiency of the pneumatic blower motor and recommend a high efficiency motor. It might also recommend a control system to turn off the motor when no milk powder is being conveyed and a variable frequency drive (VFD) to manage energy use of the motor. Those possible energy efficiency savings are, as noted above, only part of the cost and efficiency optimization opportunities for this system. By understanding the objective of the process (i.e., to convey milk powder), and by having experience with similar process requirements, Bridgestone was able to present additional ideas that would not only optimize energy use and improve efficiency, but also lower O&M costs, reduce product losses resulting from clearing a blockage, and improve the work environment (i.e., minimize fugitive milk powder). In this case, the estimated O&M and other non-energy savings almost equaled the estimated energy savings, something that may have been missed in a simple energy audit.

This example is typical of the way in which Bridgestone approaches industrial and commercial facility energy auditing and efficiency projects. As we work with our clients to optimize their industrial and commercial facility’s energy use and efficiency and lower their carbon footprint, we look to understand their systems and processes, why they are designed and work the way they do, and the details of the equipment that is employed. As our core team of energy and process engineers and consultants has decades of worldwide experience in industrial and commercial facilities design and the processes, equipment and systems that they contain, gaining this broad understanding can be accomplished quickly. With that understanding we can then develop ways in which to not only lower energy use and improve energy efficiency, but also optimize process efficiency, lower carbon footprint, and lower O&M and other costs. Sometimes it is as simple as changing or updating equipment, adding controls, or changing operating parameters. But sometimes this may mean recommending a modification or change in the overall process used and the equipment employed. We have heard many times “why should we change, that’s the way we’ve done it for 25 years.” Yes, agreed it works, but that doesn’t mean there isn’t a better way that is more efficient, uses less energy, and has a lower carbon footprint, something not considered when it was originally designed. Simply, in Bridgestone’s approach to commercial and industrial facility energy efficiency auditing, unless requested otherwise, nothing is off the table. Lots of questions get asked and answered so we examine anything that could help improve energy and operational efficiency, lower energy costs, lower O&M costs, and reduce the impact on the environment.

For more information on commercial and industrial facility energy efficiency auditing and process optimization, or to discuss your project needs, please contact us.

Post A Comment